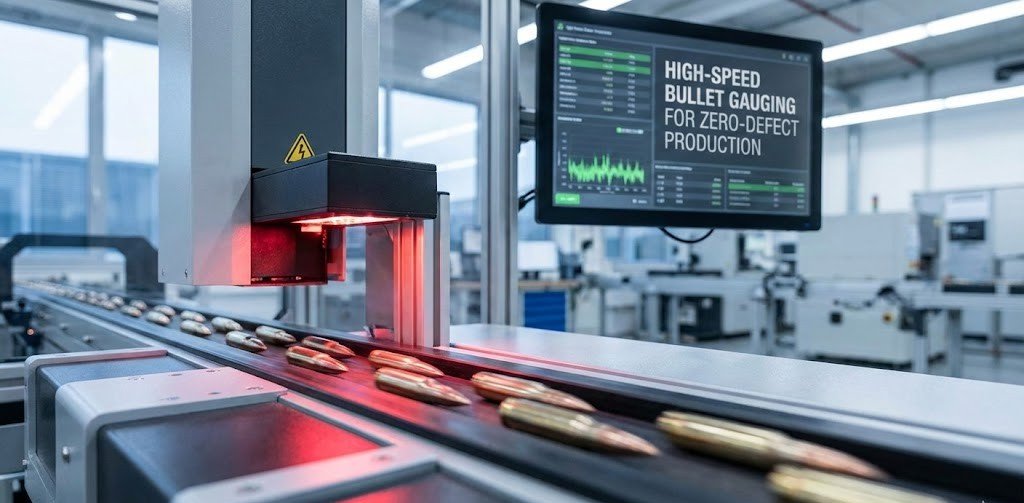

High-speed bullet gauging for zero-defect production represents one of the most transformative advancements in modern ammunition manufacturing, allowing producers to achieve consistency, precision, and safety levels that were once unattainable through manual inspection. In an industry where tolerance deviations measured in microns can influence ballistic behavior, chambering reliability, and long-term firearm integrity, the ability to verify every bullet at extremely high throughput is no longer simply a competitive advantage; it is a foundational requirement for ensuring technical excellence and process uniformity. As production volumes increase and global standards continue to tighten, manufacturers rely on advanced gauging technologies to sustain accuracy across thousands of units per hour while eliminating sources of human error that traditionally contributed to variability.

The rise of high-speed gauging systems is directly connected to the escalating demands placed on ammunition manufacturers. Modern defense, law enforcement, and commercial shooting sectors expect ammunition to behave identically across differing environmental conditions and operational scenarios. This expectation obliges producers to refine every phase of the manufacturing process, with particular emphasis on dimensional verification. High-speed gauging systems were developed specifically to address the shortcomings of traditional inspection routines by enabling rapid validation of bullet geometry without interrupting production flow. These systems preserve dimensional fidelity even as production machinery operates at maximum capacity, ensuring that the speed of manufacturing does not undermine the precision required for reliable performance.

The transition from manual inspection to automated high-speed gauging signifies more than an upgrade in technology; it embodies a change in quality philosophy. Previously, inspection was often limited to sampling methods that evaluated only a fraction of total output. While practical under older production environments, sampling cannot guarantee uniformity when production scales increase and tolerance requirements tighten. Automated gauging ensures that every bullet is measured, analyzed, and classified individually. By replacing selective validation with continuous inspection, manufacturers eliminate the statistical uncertainties inherent in sampling and move toward genuine zero-defect outcomes.

Dimensional integrity is the foundation of zero-defect ammunition production. Every component in a cartridge must perform within narrow design limits, and the bullet is one of the most influential variables in determining ballistic performance. High-speed gauging validates dimensions such as diameter, overall length, ogive profile, surface finish, jacket alignment, and concentricity. Even slight deviations in these parameters can affect chamber pressure, velocity consistency, feeding reliability, and downrange accuracy. The pursuit of zero-defect output depends on eliminating these irregularities before the bullet advances further along the assembly line.

The ability to maintain dimensional stability during mass production requires inspection systems capable of identifying variations faster than human vision or manual tools could ever detect. When properly calibrated, a high-speed gauging machine captures geometric details with extraordinary precision. Each pass through the gauging chamber produces a multi-dimensional profile that is analyzed in real time. The system compares this data against defined tolerance thresholds, rejecting any bullet that fails to meet specifications. This continuous verification process prevents defective components from reaching later stages of production where defects become more costly to correct.

High-speed bullet gauging systems depend on advanced optical, laser, and digital measurement technologies. Laser micrometers traverse the bullet’s profile, producing accurate readings of diameter and contour. Vision-based systems analyze the external geometry using controlled lighting that enhances surface detail and highlights imperfections. High-speed linear encoders track position and movement with precision, while machine learning software refines interpretation accuracy through continuous model adjustments. Each of these technological components contributes to an environment where the bullet’s geometry is recorded with exceptional speed and resolution.

The gauging process is entirely contactless, ensuring that sensitive bullet surfaces remain untouched throughout measurement. This is especially important for precision-grade ammunition where even minor scratches or micro-abrasions can introduce performance inconsistencies. Contactless measurement also minimizes the risk of contaminating or deforming the bullet, preserving its structural integrity for downstream processes. As the bullet passes through the system, sensors collect data in fractions of a second, allowing thousands of units to be examined per hour without slowing production.

Integrating high-speed gauging into a continuous production line offers substantial operational benefits. Rather than functioning as a standalone inspection checkpoint, the gauging machine becomes an active component of the manufacturing ecosystem. Bullets arriving from forming, swaging, or finishing stations move directly into the gauging system, where they are measured automatically. Compliant units advance toward loading, crimping, or final finishing processes, while non-compliant units are diverted for rework or disposal. This seamless integration ensures that defects are identified before additional labor or materials are invested into flawed components.

The capacity to sustain uninterrupted inspection during high-speed production cycles enables manufacturers to maintain consistent output even during peak demand periods. Real-time data streaming from the gauging system provides insight into machine wear, process drift, and mechanical misalignment. Operators can interpret these indicators to make timely adjustments, preventing small deviations from becoming serious production issues. As a result, the production line operates with greater predictability, reduced waste, and improved overall efficiency.

Human error has historically been one of the most significant contributors to manufacturing inconsistencies in ammunition production. Even experienced workers cannot maintain the precision, speed, or consistency required for modern ballistic standards. Fatigue, distraction, and natural variation in manual measurement techniques introduce discrepancies that compromise product reliability. High-speed gauging eliminates these risks entirely by removing human judgment from the critical measurement phase.

Automated systems apply identical measurement criteria to every bullet, guaranteeing uniform inspection quality throughout each shift. They do not tire, lose focus, or vary their measurement pressure, ensuring that every unit is evaluated under exactly the same conditions. This strict uniformity represents a crucial step toward the realization of zero-defect production. The machine does not overlook minor defects that a human operator might ignore under pressure or fatigue, nor does it misinterpret dimensions due to subtle handling inconsistencies. This automation creates a quality ecosystem defined by objective precision rather than subjective interpretation.

One of the most remarkable achievements in modern ammunition manufacturing is the ability to increase inspection speed without compromising measurement accuracy. Early industrial systems often sacrificed accuracy for speed, or vice versa. High-speed gauging machines overcome this limitation through synchronized sensor arrays, optimized processing algorithms, and stable mechanical design that supports continuous motion. The system maintains precise alignment despite rapid throughput, ensuring that each bullet is measured in exactly the same spatial orientation and under identical sensor conditions.

This relationship between speed and accuracy enables manufacturers to achieve true mass production without diminishing quality standards. High-speed gauging systems are engineered to handle large volumes for military, commercial, and defense-sector applications where consistent reliability is essential. The ability to verify every bullet at extreme speed reinforces the integrity of the entire production line, ensuring that increased output does not increase defect probability.

Data intelligence generated by high-speed gauging machines plays a profound role in shaping zero-defect production strategies. Each measurement is recorded, analyzed, and stored in a digital archive that allows manufacturers to examine long-term trends. This historical data highlights patterns that reveal mechanical wear, material inconsistencies, calibration drift, or operational inefficiencies. Manufacturers can implement proactive corrections based on real-time insights rather than waiting for defects to accumulate.

Predictive analytics now serve as a core component of zero-defect strategies. By identifying early signs of tooling fatigue or misalignment, the system prevents dimensional deviations before they reach a scale that affects overall output. This proactive approach strengthens the reliability of the production environment, enhances equipment longevity, and reduces the frequency of unexpected downtime. Data intelligence transforms inspection from a reactive process into a continuous improvement cycle guided by measurable insights.

Surface quality is an essential dimension of zero-defect production because even structurally sound bullets can fail operational expectations if surface flaws remain undetected. Imperfections such as micro-cracks, dents, or irregular coatings can influence friction behavior, chamber engagement, feeding consistency, and aerodynamic stability. High-speed gauging machines equipped with vision inspection capabilities verify surface characteristics with exceptional sensitivity. They detect variations that would escape visual inspection entirely, ensuring that surface consistency aligns with geometric precision.

Surface quality management also enhances downstream assembly and ballistic performance. A bullet free of surface deformities cycles more smoothly, experiences less wear during chambering, and maintains stable rotational balance during flight. Integrating surface inspection into the high-speed gauging process ensures that both internal geometry and external characteristics contribute to the zero-defect objective.

Environmental stability plays a substantial role in maintaining measurement reliability. Manual gauges often respond unpredictably to temperature fluctuations, humidity changes, and ambient vibration. High-speed gauging systems are engineered with environmental compensation algorithms that adjust sensor readings automatically. This internal stabilization protects measurement accuracy even under dynamic factory conditions. The ability to maintain consistency across environmental variables reinforces the zero-defect philosophy by preventing external influences from distorting critical measurements.

Sustaining long-term accuracy requires disciplined calibration and maintenance routines. High-speed gauging machines undergo scheduled alignment checks to ensure that sensors maintain their positional accuracy. Calibration routines validate laser and vision systems against certified dimensional standards. Preventive maintenance activities such as cleaning optical components, lubricating mechanical segments, and updating software frameworks extend equipment longevity and protect measurement stability.

Maintenance of this nature forms the backbone of a zero-defect production environment. When gauges remain perfectly calibrated and structurally sound, manufacturers can trust the machine’s output implicitly, allowing them to maintain high-volume production without compromising precision.

The future of high-speed bullet gauging is closely connected to advancements in automation, artificial intelligence, and digital manufacturing. Emerging technologies will enhance the speed, accuracy, and decision-making capabilities of inspection systems. AI-driven defect classification, adaptive measurement algorithms, and autonomous calibration procedures will refine inspection accuracy even further. High-speed systems will evolve into predictive control units that not only measure defects but also adjust production parameters in real time to prevent deviations before they occur.

Integration with digital twins and cloud-based analytics platforms will allow manufacturers to simulate full production cycles, test optimization strategies virtually, and deploy improvements with unprecedented precision. As ammunition manufacturing becomes increasingly driven by digital intelligence, high-speed gauging will remain a core pillar of zero-defect production strategies.

High-speed bullet gauging contributes to the advancement of ammunition quality across the entire industry. Manufacturers embracing this technology position themselves at the forefront of reliability, safety, and performance assurance. Zero-defect output strengthens customer trust, enhances contract viability, and aligns manufacturing operations with the rigorous expectations of modern defense and commercial sectors. The adoption of high-speed gauging marks a commitment to excellence that reverberates throughout every stage of production, setting new industry benchmarks for precision-driven manufacturing.

The continuous evolution of high-speed bullet gauging will ensure that ammunition production remains aligned with the growing need for flawless performance. As global demand increases and ballistic requirements become more sophisticated, high-speed gauging systems will remain indispensable tools for achieving zero-defect outcomes and securing long-term manufacturing resilience.